Inventory Management Tips for Wholesale Quartzite Slabs

Introduction

Are you the one who is looking for wholesale quartzite slabs? If yes then stop a bit here.

The demand for the wholesale quartzite slab is always high in the market. A careful oversight with unique natural pattern and variation in weight gives a better result. The proper strategies can maintain the workflow with smoother operations and also controlled expenses.

Wholesale quartzite slabs also demand for careful oversight giving their unique natural patterns and varying weights a different go altogether. If you maintain proper strategies the workflows become smooth and eminent. And this can be the reason why businesses look to purchase wholesale quartzite slabs from certified quartzite slab suppliers or manufacturers.

Let us go through the inventory management tips for wholesale quartzite slabs.

Top 5 Essential Tips For Managing Quartzite Slab Inventory

- Track the levels of inventory: To monitor the slab quantities, location and movement of the inventory you need to track the requisite. The record of the inventory stays maintained in order. It is best if there is a possible RFID tag system or barcode scanning system to track individual slabs.

- Label and categorize accordingly: The next step is to categorize and label the inventories so that you can figure out the requirements without messing them up

- Optimizing storage: Optimizing the storage is another important step which one should do on priority basis. With this option you can store the slabs vertically and in order. Altogether you need to do is to use space-efficient racks and keep them accessed with accessibility.

- Implementing FIFO approach: The FIFO approach means first-in and first-out strategy. This is implemented to keep away the old slabs away and the newer ones in front for better view.

- Monitor the conditions: A regular check of the slabs whether they are damaged, stained or rusted is very important task. In addition to this, you need to take care of the quantity as well as the quality for accuracy rates.

- Managing leads of the suppliers: Planning ahead is mandatory if you want to avoid stock outs or any kind of overstocking.

Tip: If you look for quartzite distributors near me they will give ideas about how to implement low stock alerts, designate storage areas for climate-controlled storage for preventing damages. Using vertical storage racks for wholesale quartzite slabs are meant to increase the space and also keep them ready at reach.

How To Make Wholesale Quartzite Slabs Unique

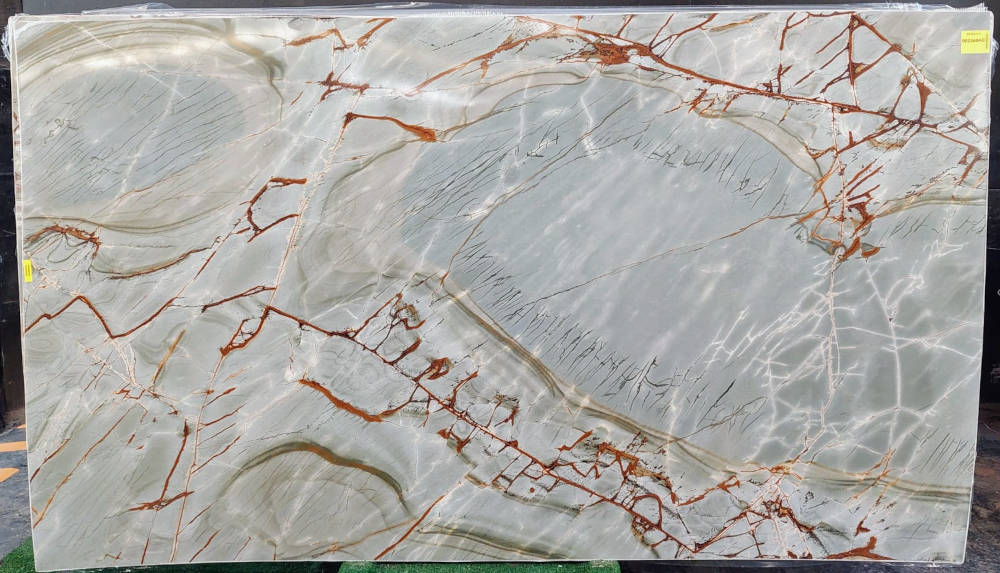

Quartzite differs in quantity and quality. Differentiating wholesale quartzite slabs begins with the custom edge profiles including designs like mitered or laminated ones. These can highlight the natural veining processes.

The quartzite slab suppliers never step back to offer bespoken finishes that count in textures like honed, brushed, or leathered ones by altering the light reflection for distinct aesthetics in luxury kitchens.

Quartzite distributors near me provide digital temptation for accurate vein book matching across islands or walls. Experimenting with the hybrid thicknesses, blended with 2cm tops and 3cm backsplashes for depth is also important. With all these modifications quartzite stone slabs beyond commodity stock, can meet client demands with originality in the high-end projects.

What Are The Benefits of Using Inventory Management for Quartzite Slabs

Effective inventory management for wholesale quartzite slabs are known to deliver gains in the operational efficiency by maintaining financial health. Yards reduce holding costs. They track the usage patterns, avoiding excess stock and also ties up capital in unused quartzite stone slabs. Real-time visibility prevents the stock outs during the hour of peak orders. The projects are maintained on schedule and customers are highly satisfied. Waste drops through optimized cut planning, maximizing yield from each slab sourced from quartzite slab suppliers. Accurate forecasting strengthens supplier negotiations, securing better terms from quartzite distributors near me. Overall, disciplined tracking turns potential chaos into predictable workflow, supporting business growth without surprise expenses.

How to Conduct Regular Inventory Audits to Ensure Accuracy and Efficiency

Remember to schedule cycle counts for wholesale quartzite slabs by checking 10 percent of the stock weekly by rotating all the available categories at hand and also check the color and thickness. Use of handheld QR scanners to match with the physical slabs against all digital records, noting discrepancies in location, condition, or quantity can ease the work for businesses dealing with quartzite supplies.

Added Tip On How To Manage The Inventory Properly

Involve many team members for conducting the cross-verification, photographing damaged quartzite stone slabs for immediate documentation. Reviewing the findings immediately, adjusting reorder points and the storage layouts can save much time in business. These kind of audits from quartzite slab suppliers batches maintain precise counts, preventing the losses, and streamlining operations for steady efficiency at work.

Concluding Lines

Mastering inventory management transforms handling of wholesale quartzite slabs from routine task to strategic advantage. Plots achieve lean operations by forecasting demand, organizing storage, and conducting regular audits with quartzite slab suppliers like Stonex USA. Clients secure steady supply from quartzite distributors near me while minimizing waste on quartzite stone slabs. These practices cut costs, speed workflows, and open paths to customization that sets projects apart. Those businesses who are adopting a disciplined tracking position for sustained growth amid shifting markets are gaining a lot.

Tip: Steady application yields reliable results over passage of time.

Frequently Asked Questions

Q1. What challenges arise in managing wholesale quartzite slabs inventory?

Ans: Wholesale quartzite slabs vary in weight and pattern, complicating storage and tracking. Yards face issues like edge damage from mishandling, inconsistent supplier lead times, and demand spikes during remodel seasons. Proper racking, digital logs, and safety stock help mitigate these risks.

Q2. How often should audits occur for quartzite stone slabs?

Ans: You should conduct weekly cycle that counts coverage of 10 percent of quartzite stone slabs which rotates by type or age. Full annual audits can verify everything. This frequency catches the possible errors early without ceasing the business operations.

Q3. Can quartzite distributors near me assist with inventory planning?

Ans: Quartzite distributors near me are actually searched for to get the record of the sales relating to trending data and lead time estimations. They provide samples for testing demand and flexible ordering to match the forecasts. Building these relationships helps in creating a precise stock levels.